Buschman's Clutch Bleed Method

This is the clutch bleed method I came up with when installing my

McLeod Master Cylinder. Other than the M/C itself the tools I needed

where: Your Old Slave Cylinder, Dremel tool, GM OEM Spec Brake fluid

(only one bottle was needed, but much recycling took place), Mity Vac

Pump, Zip Tie, Small Rubber Washer.

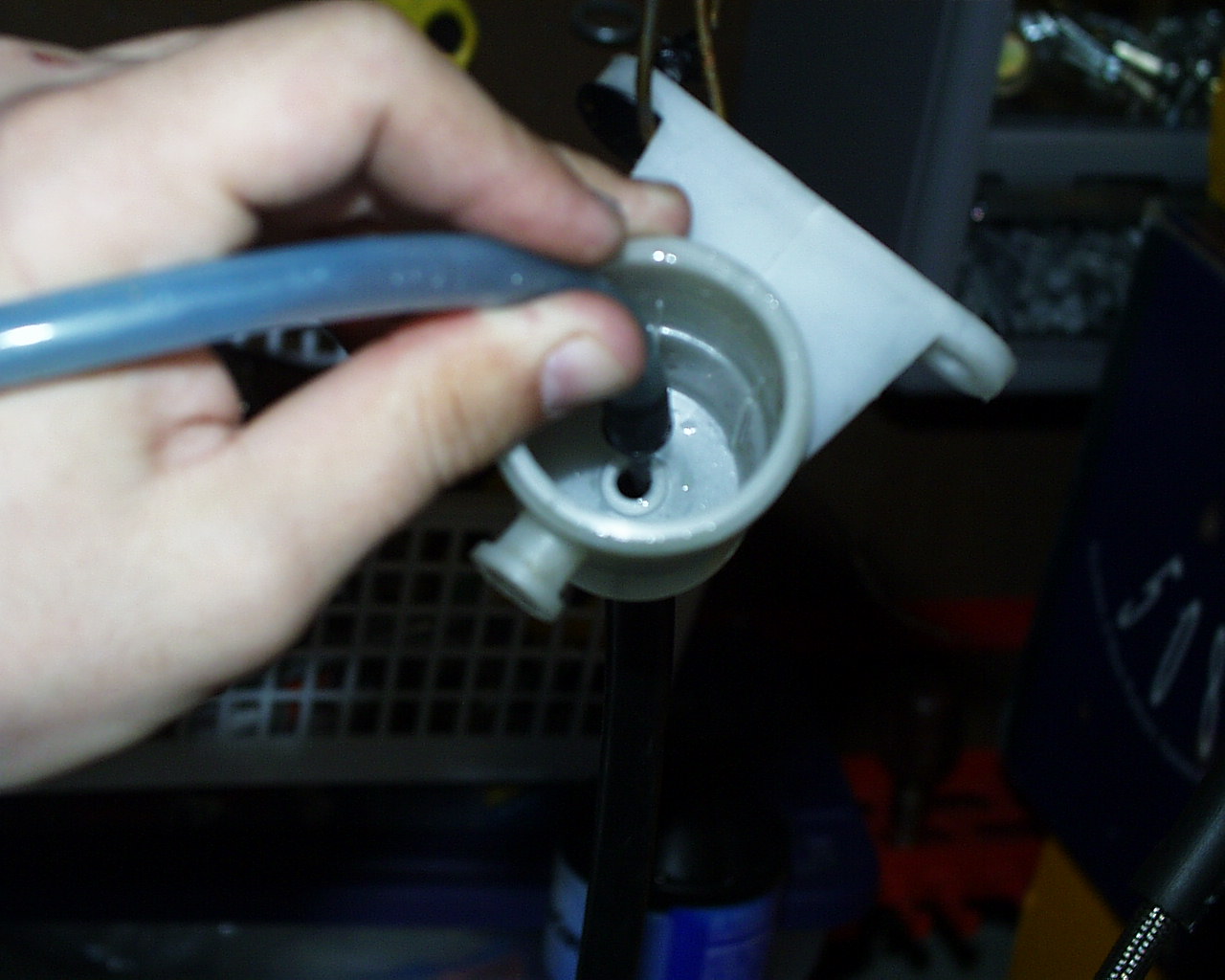

Ok the first thing I did was to create this little helpful tool. I’ll

call it a slave sim. Cause basically it’s job is to act like the slave

cylinder, open up the hydraulic valve, and allow me to pull the fluid

through the Master cylinder in the direction of the slave cylinder.

I basically removed the female end of the Slave’s hydraulic connection

by removing the pin (same pin setup as the M/C) and the connector slid

right out. ***Not that you need it for this clutch bleed but if you

happen to tear your M/C washer you will find the exact same sort of

washer sealing the Slave’s female connector. So you might want to store

it somewhere just incase.***

Save yourself a half hour of frustration and Dremel out the inside of

the tubing. It will make slipping the tube over the Slave's hydraulic

connector so much easier. Be sure to clean out any and all loose rubber

if you do Dremel the inside. I put just a little bit of grease around

the tube to help slip it on.

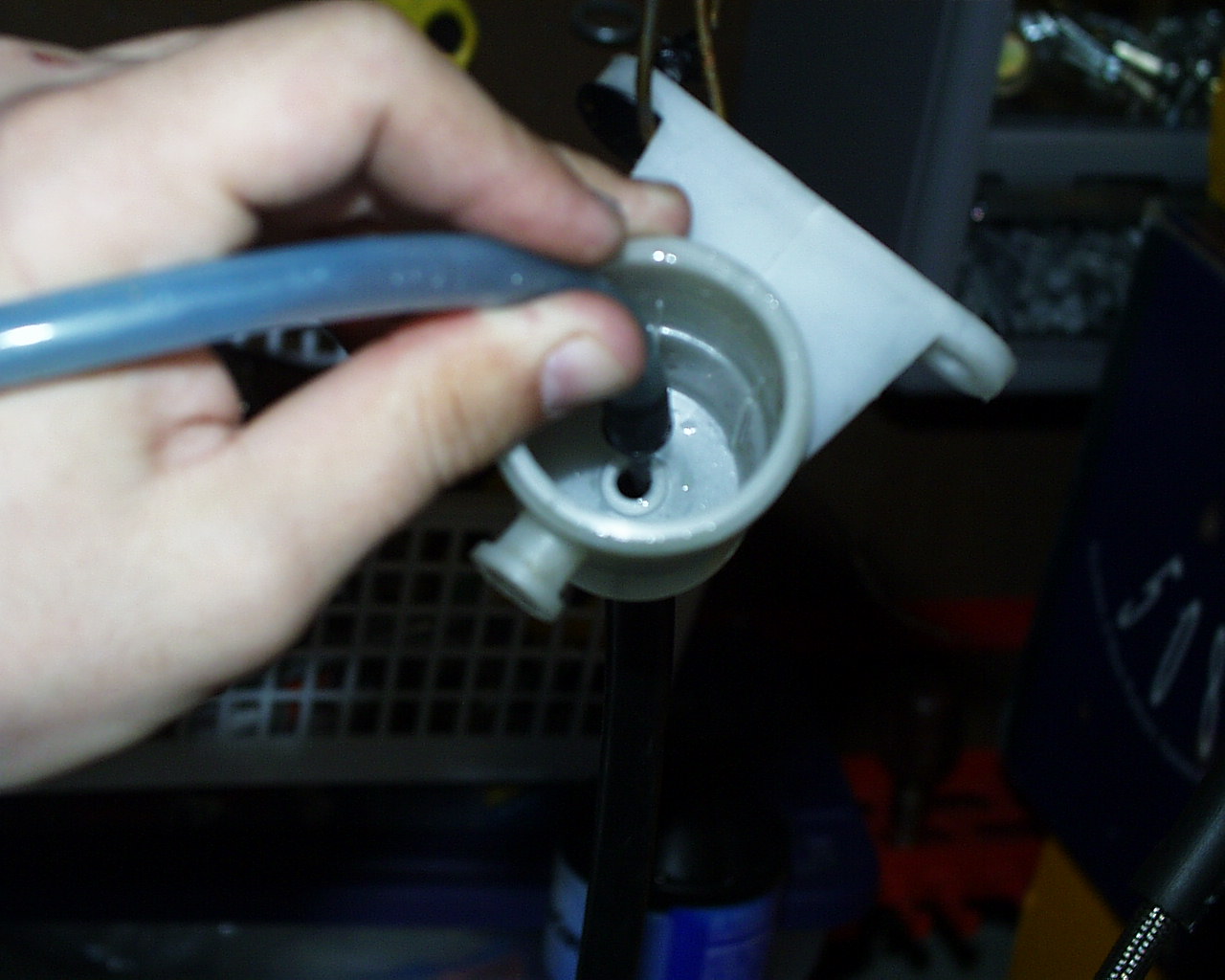

I placed a small rubber washer in the gap of the female connector. Not

so much to seal the tube but just to help get the tube past that gap.

The tubing came straight from the Mity Vac kit I got. I just cut one of

the longer tubes in half. They are the perfect size for this job. Once

the tube is on securely, zip tie it and you’ll have an airtight seal.

Here you’ll see the M/C setup to be bleed. Forgive me for using a stock

M/C in my pictures, but the McLeod is in and working. I’m certainly not

gonna rip it out to take pictures of it. :p

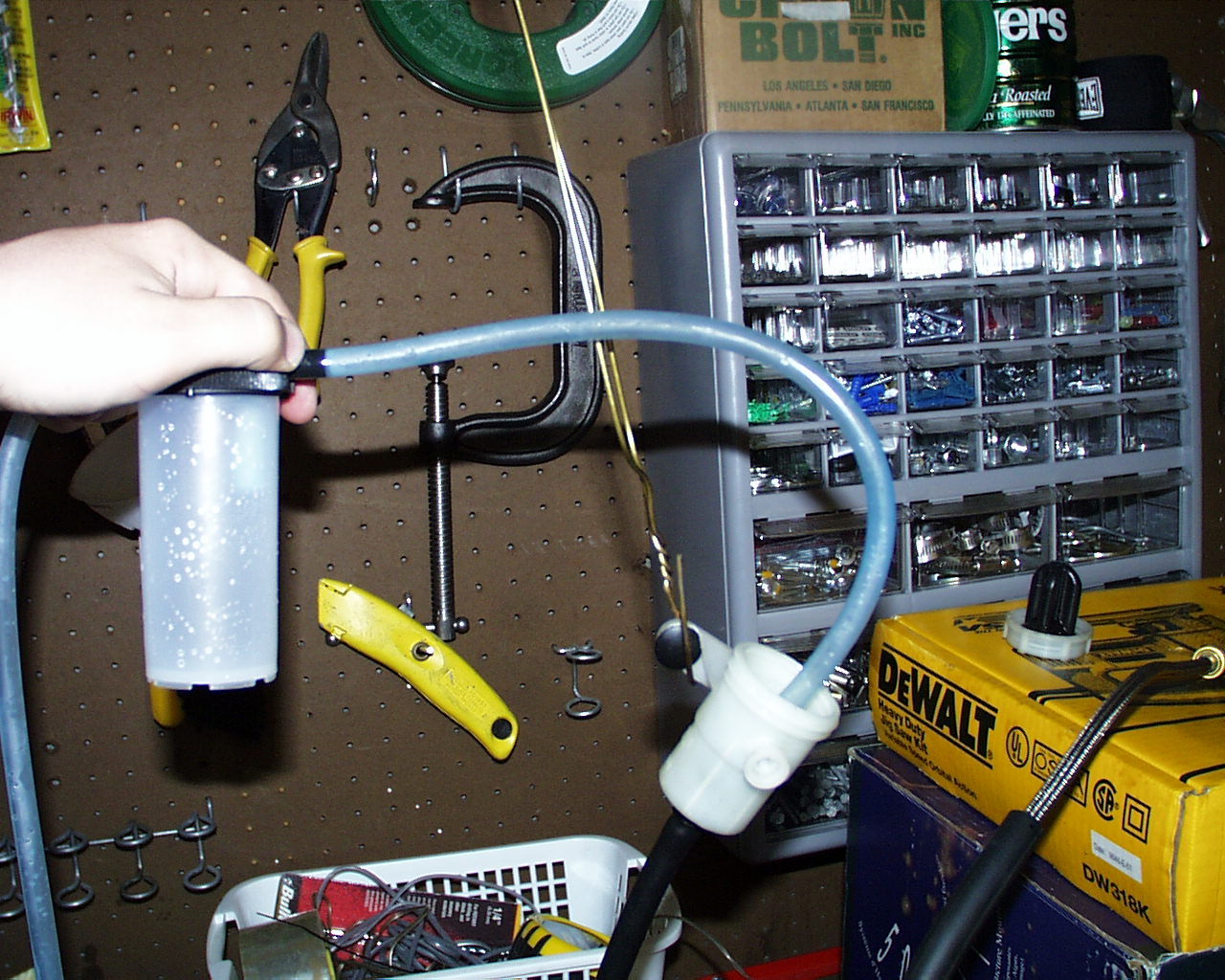

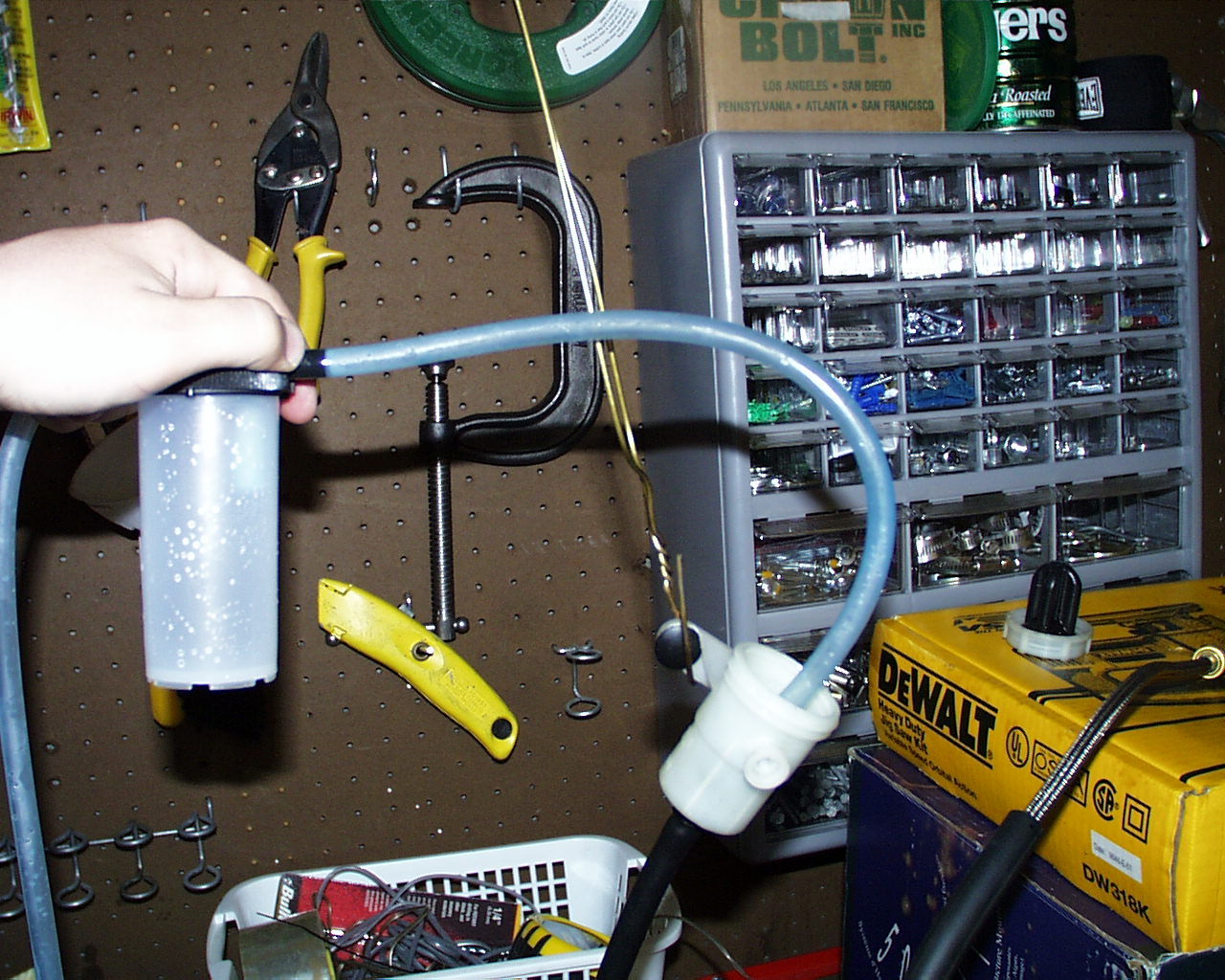

So I’ve mounted the M/C horizontally in the vise. I’ve removed the

reservoir, but left the reservoir tube and ran it into a plastic

container filled with brake fluid. Be sure to keep the brake fluid

level above the tube opening at ALL TIMES! Otherwise, you’ll suck air

back into the system and have wasted all the time you just spent

bleeding.

Now I have the hydraulic line running upwards to help the air get out

of the system. This is probably overkill since the Mity Vac is sucking

the air out, but it isn’t hurtin either. As you can see from the

picture, I have my slave sim connected to the hydraulic line and

running into the Mity Vac’s vacuum container.

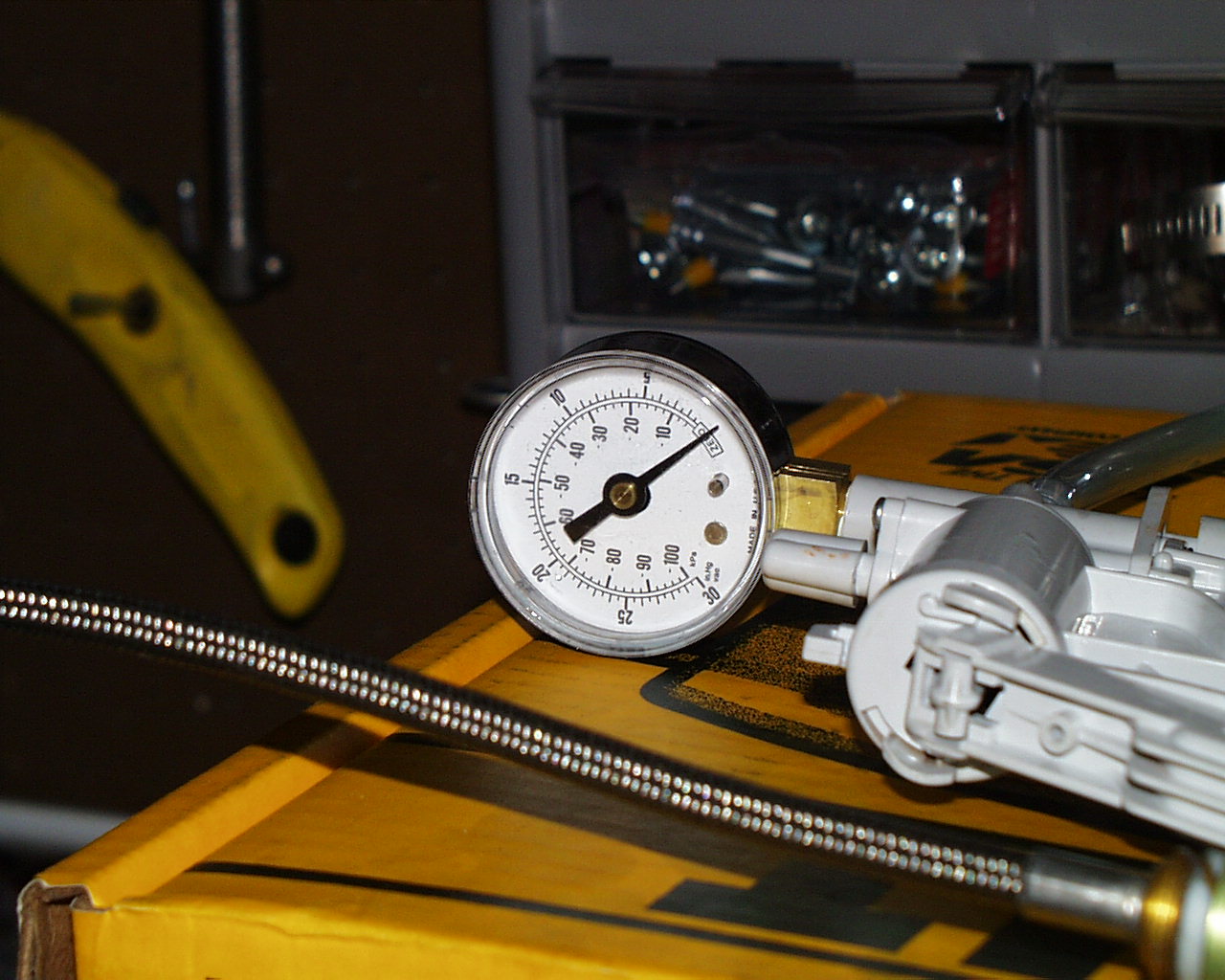

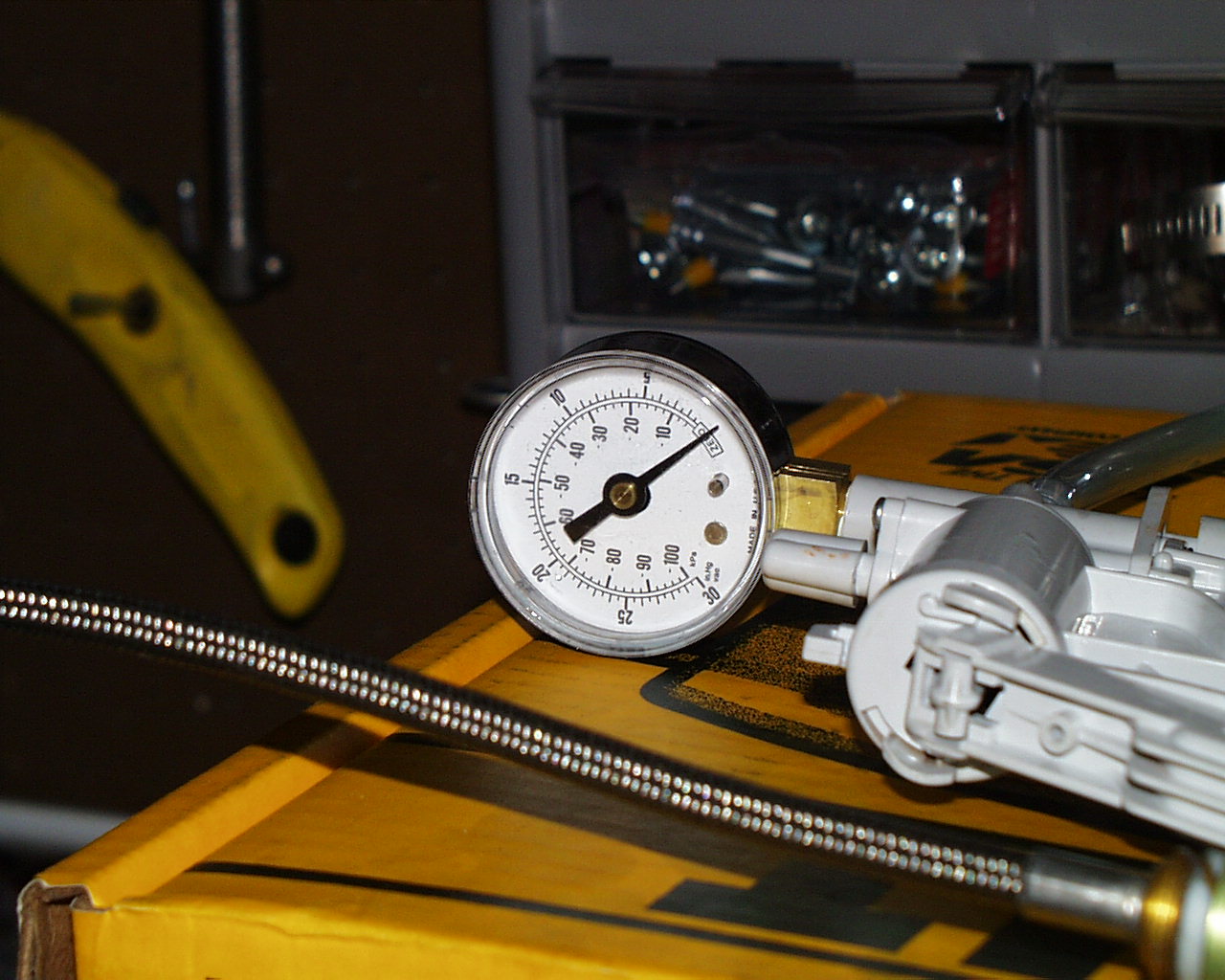

The first step is simple. Pump up the Mity Vac to 5 psi and let the

pump pull out the air and fluid. Obviously when your Mity Vac’s

container get near full empty it into the plastic container that feeds

the reservoir tube. Continue to go through this cycle until you don’t

see any more air being removed. Then, go up to 10 psi. Repeat the cycle

until there are no more bubbles. Then go to 15 and then 20 psi. Every

time you bump up you’ll magically see more air. At 20 psi you might

notice the bubbles start to aerate a little bit (kinda looks like soap

suds if you’re not familiar). Don’t worry about those; we’ll get those

later. Just try and eliminate the normal air bubbles.

OK so now onto the second step. A little more complicated, but you’ll

get all the “trapped air” with this method. The M/C should be setup

exactly the same as in the first step. The only possible change would

be the size of the tube inside the Mity Vac’s vacuum container. This

picture does quite illustrate it so well but you need to connect the

tube that “almost” reaches the bottom of the container. If you were

already using that one, then you’re set. If not put that tube in now.

To start you’ll need to pump the Mity Vac quickly and build up 20 psi

of pressure as fast as you can. The Mity Vac’s container should be

filling fast. Wait till it hits about the halfway mark (the fluid level

needs to be at least an inch to an inch and a half above the bottom of

the tube so no air is sucked in). Once your fluid level is high enough

slowly pump the M/C’s clutch pedal rod in all the way and slowly let it

out. You’ll notice a ton of air released at this point. When you pump

the clutch pedal rod in, the fluid flows into the container rather

quickly. When you let the clutch pedal rod out it sucks whatever air

and fluid are in the the Slave Sim tube back in (this is why it’s

important to have the fluid level above the tube so no extra air is

sucked in). The Mity Vac will not be able to suck any fluid unless the

clutch pedal rod is completely released. Once the rod is back out the

Mity Vac will get all those air bubbles you just shook loose. (You can

use the trigger on the Mity Vac to quickly release pressure so your

fluid level does not go past the top of the Mity Vac’s vacuum

container) Continue to do this till you don’t see any more bubbles.

You’re 95% done now. However there is one spot where air can still

hide. To get these bubbles we have to change the setup a little bit.

First off remove the Slave Sim from the Mity Vac (We’re done with the

Slave Sim) and disconnect it from the hydraulic line. (The clutch pedal

rod should be rock solid and you’ll not be able to push it in with the

hydraulic line closed)

Remove the Reservoir tube from the container and reinstall the actual

reservoir. Now you need to find a way to hang it up so that it sits

vertically (I mangled a couple of coat hangers for this duty)

On the Mity Vac attach a different tube in place of where the Slave

Sim’s tube was attached. To that tube you need to find one of those

little nozzle accessories. You can see from this photo that it needs to

be one of the nozzles that look like a pencil tip.

As you can see from this picture, that nozzle has to fit “inside” the small hole at the bottom of the reservoir.

With your hydraulic line disconnected and closed and your reservoir

filled and vertically suspended you are ready for the Mity Vac. Before

inserting the Mity Vac be sure to fill the tube holding the nozzle with

brake fluid. You don’t have to fill it up all the way, but at least 4-5

inches worth of brake fluid in that tube (about the halfway mark).

Snuggly insert the Mity Vac’s nozzle into the small hole at the bottom

of the reservoir. Your setup should look something like this by now:

Pump the Mity Vac up to 20 psi and you might find a few bubbles pulled

out. Be sure the nozzle is snuggly in that hole; otherwise you’ll just

pull fluid out of the reservoir. I want to get any air that might be

trapped in the reservoir tube or inside the M/C. Once any bubbles are

pulled you can use the trigger to release the pressure and try it

again. Keep doing this till no bubbles are pulled. Be sure to always

keep at least 4-5 inches of brake fluid in the Mity Vac’s nozzle tube,

else when you release pressure air can get sucked right back into the

M/C.

That’s it! You’re done! Make sure the Reservoir is filled enough, put

your moisture lock back in and recap the reservoir. You’re M/C is now

ready to install. Assuming you’re slave is properly bled, then nothing

else needs to be done to the M/C and you should be able to just install

it and start bangin gears!

Contact buschman_007@yahoo.com

with questions or problems with this service.